Liquimech Solutions(s) Pte Ltd

#06-42 Unity Centre,

Singapore 658077

FAX : +65-6896 7115

EMAIL : sales@liquimech.com

-

ITT Goulds

-

Roto Pumps

-

WorldChemical Pumps

-

GM Fluidtech Pvt. Ltd

-

Fenix Process Technologies

-

Vee Bee Filtration

-

Primary Fluids

-

Procedyne

-

Elmac

-

BGR Energy

-

Indra Valves

-

PK VALVE

-

DEL TECH

API-610 PROCESS

Model 3700

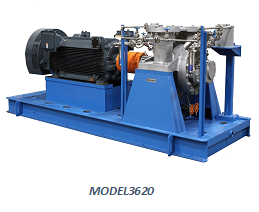

Model 3600 & 3620

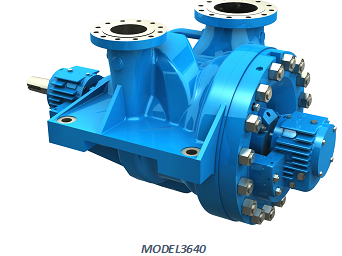

Model 3640

Model 3910

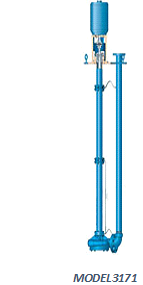

Model 3171

Model 3700 & 3710

High temperature and high pressure process pumps designed to fully meet the requirements of API-610. Centerline support for high temperature stability, maximum rigidity. Tangential discharge for maximum hydraulic efficiency.

Available in top suction design (Model 3710).

· Capacities to 6,500 GPM (1,475 m3/h)

· Heads to 1,150 feet(350 m)

· Temperatures to 800 F (427 C)

· Pressures from full vacuum to 870 PSIG (6,000 kPa)

Materials: Carbon Steel, 12% Chrome, 316SS, Duplex SS, other high alloys.

Model 3600 & 3620

High Temperature Double Suction

Between bearings, radially split process pumps designed for smooth, reliable operation. Fully meets requirements of API-610.

· Capacities to 20,000 GPM (4,540 m3/h)

· Heads to 1,500 feet(455 m)

· Temperatures to 850 F (455 C)

· Pressures to 1,000 PSIG (6,895 kPa)

Materials: Carbon Steel, 12% Chrome, 316LSS, Duplex SS, other higher alloys.

Model 3640

High Temperature Two-Stage

Between bearings, radially split process pumps designed for smooth, reliable operation. Meets toughest specification requirements of API-610.

- Capacities to 1,500 GPM (340 m3/h)

- Heads to 1,400 feet(425 m)

- Temperatures to 850 F (455 C)

- Pressures to 750 PSIG (5,170 kPa)

Materials: Carbon Steel, 12% Chrome, 316LSS, Duplex SS, other higher alloys.

Model 3910

Bearing Frame In-Line

High Pressure, high temperature services meets API-610 requirements. Back pull-out for ease of maintenance. Bearing frame carries pump loads.

- Capacities to 7,500 GPM (1,700 m3/h)

- Heads to 750 feet(229 m)

- Temperatures to 650 F (343 C)

- Pressures to 595 PSIG (4,100 kPa)

Materials: Carbon Steel, 12% Chrome, 316LSS, Duplex SS, other higher alloys.