Liquimech Solutions(s) Pte Ltd

#06-42 Unity Centre,

Singapore 658077

FAX : +65-6896 7115

EMAIL : sales@liquimech.com

-

ITT Goulds

-

Roto Pumps

-

WorldChemical Pumps

-

GM Fluidtech Pvt. Ltd

-

Fenix Process Technologies

-

Vee Bee Filtration

-

Primary Fluids

-

Procedyne

-

Elmac

-

BGR Energy

-

Indra Valves

-

PK VALVE

-

DEL TECH

Progressive Cavity Pumps

The pumping element comprises of a precision machined single external helix metallic rotor, and a double internal helix elastomer stator. Due to the special profile of the rotor and stator set, a sealing line is formed along the axis of the rotor which is maintained at both static and dynamic conditions.

Industrial Pump:

Roto Xtra Value Progressive Cavity pumps are of heavy duty construction and are designed to pump ‘tough – to – handle’ fluids with ease. The construction of these pumps is based on the modular concepts and incorporate next generation pumping elements (molded to metal) stator, solid shaft and double sealed Cardan Universal Joints for improved performance and longer service life.

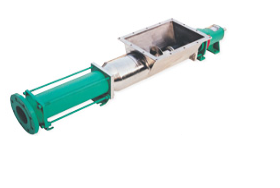

Wide Throat:

Wide throat type inlet allows gravity flow of highly viscous (plastico – Viscous) material on to the augur-on-coupling rod which pushes the substance to the pumping element. Wide throat pumps with the twin paddle bridge breaker arrangement at the top are designed for handling extremely difficult media with very high solid content and non – flowing properties.

Vertical pumps:

These vertical pumps are designed to operate with the pumping elements immersed in the product. They are custom designed and are manufactured for varying column length to suite the pump depth. The suction port of all the pump sizes are designed so that a strainer can be attached to prevent and large solids entering the pump.

Food Pump:

These pumps are designed for handling food applications. All metallic parts in contact with the medium being handled are fabricated in smooth finish stainless steel. These pumps are standard with closed universal joints enabling it to handle fluids which are poor lubricants like aerated or dematerialized water as well as lubricating type applications.

Dosing Pump:

These pumps are developed for low flow applications that demand high accuracies and repeatability with unique advantages of smooth, laminar & pulsating free flow.

Mining Pump:

Roto MR/RM are based on classical design retaining its compact and robust construction. These pumps have combined bearing and pump housing and incorporate hollow shaft which accommodates the coupling rod, thereby reducing overall length of the pump.

Features & Benefits

Positive Displacement:

Because of single rotating element, progressive cavities are generated which deliver a uniform, metered and non-pulsating flow. The head developed is independent of the rotational speed, where as the capicity is proportionate to the speed.

Self priming:

Inherently self-priming, the pumps can work on snore and do not requier foot valve.

Non-Clogging:

Can handle solid in suspension or medias contaning a high percentage of solids.

Low NPSH Requirement:

Suction lift capabilities of up to 9.5mwc and effective in high vacuum coditions.

Reversible:

Due to the reversible rotation capabilities, progressive cavity pumps can preform with equal efficiency in either direction.

Industrial Pump:

These pumps are available in bare shaft and close coupled configuration. 6 and 8 stages in select sizes. A variety of material of construction, shaft sealing options are also available.

Wide Throat:

Available in close coupled and bare shaft configuration. Custom designed hopper is possible. A variety of material of construction, shaft sealing options are also available.

Vertical pumps:

These pumps are available in only close coupled configuration. A variety of material of construction, shaft sealing options are also available.

Food Pump:

Available in close coupled and bare shaft configuration. Sealing is by Hygienic quality packed gland or Mechanical Seal. These pumps are also available with CIP port configuration. For high viscous and difficult to flow liquids these pumps are also available with wide throat configuration.

Dosing Pump:

These pumps can handle wide variety of fluids ranging from clean and clear liquids to abrasive, Corrosive, viscous and solid laden media. The repeatability accuracy has been less than 1% fluctuation.

General Purpose Pump:

Light Industrial and Agriculture DC series:

Capacities upto 6.5 M3/hr (29 GPM)

Pressures upto 3 Bar (44 Psi)

Mini Range MC Series:

Capacities upto 3.5 M3/hr (15 GPM)

Pressures upto 3.5 Bar (50 Psi)

General Purpose SC series:

Capacities upto 12 M3/hr (54 GPM)

Pressures upto 3.5 Bar (51 Psi)

Mining Pump:

These pumps are available in both free molded and molded to metal stator designs. The maximum pressure for Free Molded pump is up to 9 Bar and for molded to metal up to 12 Bar.