Liquimech Solutions(s) Pte Ltd

#06-42 Unity Centre,

Singapore 658077

FAX : +65-6896 7115

EMAIL : sales@liquimech.com

-

ITT Goulds

-

Roto Pumps

-

WorldChemical Pumps

-

GM Fluidtech Pvt. Ltd

-

Fenix Process Technologies

-

Vee Bee Filtration

-

Primary Fluids

-

Procedyne

-

Elmac

-

BGR Energy

-

Indra Valves

-

PK VALVE

-

DEL TECH

Spares

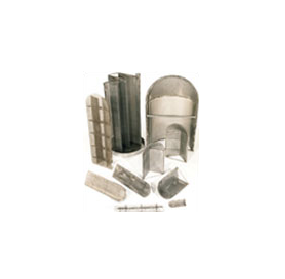

Vee Bee uses only premium suppliers and high quality materials for their Straining and Filtering elements. Cheaper Strainer and Filters may use cheaper, lower quality materials.

Genuine Vee Bee internals are precision made offering the highest quality achievable for each individual requirement and ensuring the prolonged life of your system.

Strainers and Filters by their very nature lose their effectiveness as they become contaminated; this is exactly their function. The pressure drop across the Strainer or Filter MUST be monitored to ensure that internals are properly maintained and cleaned or replaced as required (without monitoring how would you ever know that the internal was blocking up through contamination build up?).

The interval between shutdowns for inspection, cleaning or changing internals may vary under different system conditions. The life of the internal is totally dependant on the operating conditions; these parts cannot simply be fitted and forgotten. When there is a change in differential pressure it means that the internal is catching contamination, this alarms you to the potential failure of upstream equipment, take it seriously.

An efficient strainer or filter means:

• Better system economy and flow

• Lower Operating costs

• Reduction in un-planned shutdowns

• Reduced maintenance time and costs

• Less wear and tear to vital parts of equipment

Poor quality materials/equipment may cost less, but the little money that you save can become quite costly. Why gamble with the life of your system? You sell a quality product so ensure that its quality is maintained.